Subscribe to Our Newsletter

From time to time we will tell you about events, promotions, specials, coupons, new services, and new products.

We won’t share your information with anyone.

3D printing has come a long way since the 1980’s when it first made an appearance. In the 21st century, advancements for this 3D rendering technique have enabled us to create anything from metal mechanical parts to plastic prototyping tools –quicker and more efficiently than what could be done in the past. Whether it’s a final product or a prototype to get your idea on its way, there is a printer and material suited to your project. For many when they think of 3D printing, the uses are limited to these ideas of mechanical parts and prototyping in the industrial realm.

This past month at Rapids, our 3D Printing team was shown a new level of importance on how 3D printing can impact others. 3D printing is normally thought of as prototyping mechanical parts, and over the years, a majority of the projects we have produced have fit into that realm. That was until a special project came into the shop that changed our outlook on how 3D printing can be useful in less commercial ways. It can even serve a purpose to the community by bringing a new spin on an old tool, and to those who need it most.

The Iowa Educational Services for the Blind and Visually Impaired is one of the few of its kind, established in Vinton, Iowa. The school’s mission is a simple goal but a crucial undertaking by its staff and sponsors:

The Iowa Educational Services for the Blind and Visually Impaired is one of the few of its kind, established in Vinton, Iowa. The school’s mission is a simple goal but a crucial undertaking by its staff and sponsors:“Our mission is to enable Iowa’s students who are blind or visually impaired to function as independently as possible in all aspects of life by providing appropriate educational opportunities, resources,

and support services.”

One of the unique tools used to allow students the same tools in mathematics is the Draftsman Board, created by the American Printing House for the Blind. The idea behind this board is simple. When a student draws a line on the board’s surface, it creates a raised mark which can then be traced in order to see what was drawn. The surface of the Draftsman Board works by applying a vinyl sheet on top of the rubber surface of the board, which then responds to the pressure of drawing over it. Check it out here!

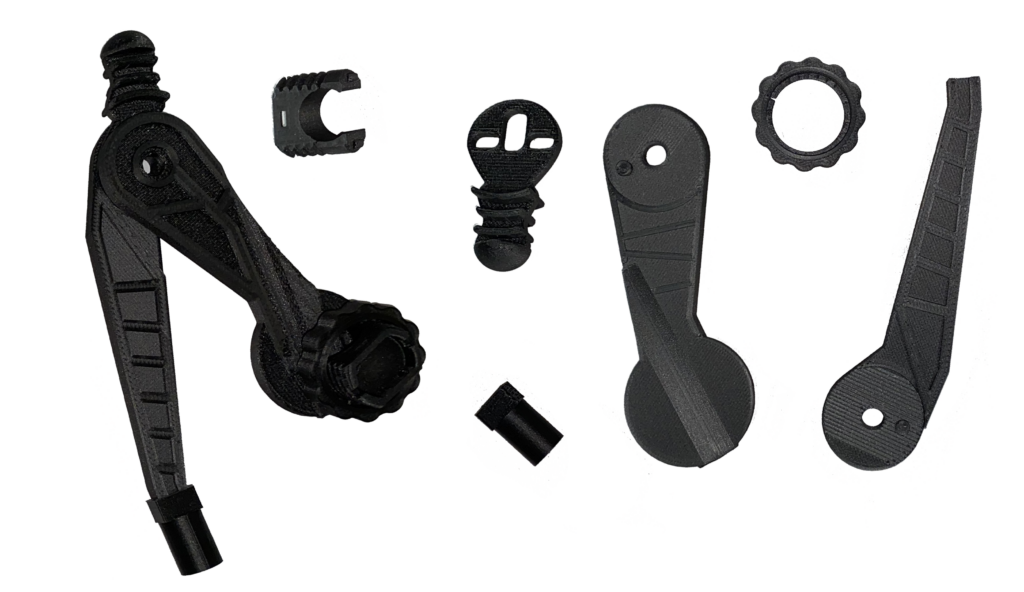

While printing one of these compasses is of great help to its new owner, it couldn’t be done without the assistance and design work of Meghan McHugh, Production Engineer at 3M in Menomonie, Wisconsin. Without the proper tools available on the market, Meghan was responsible for the creation of the compass plans to meet the needs of the school and its teachers. Meghan’s design means that these types of compasses can be printed on demand so long as a willing printer is found. The compass is one example out of multiple designs geared toward health and education, and just goes to show what a little 3D modeling and ingenuity can do!

Math Consultant Sara Larkin reached out to us after no luck with finding another printer, and a tight schedule on when the parts were needed. At our Cedar Rapids location, we have an array of eight 3D printers on standby to be able to produce a variety of orders at any given time.

While the compass for this order was originally intended to be built of the conventional ABS plastic, our systems use a composite plastic of Nylon and chopped Carbon Fiber which produces a superior part to ABS as far as strength and surface finish. Not only is it sleeker than ABS printing, but the difference is also a lighter-weight and remarkably durable build. Our parts are less prone to warping while printing and rugged enough to handle everyday use.

From time to time we will tell you about events, promotions, specials, coupons, new services, and new products.

We won’t share your information with anyone.

|

Uploaded

Failed

|

|